Semiconductor Ultra Clean Solutions

Semiconductor Ultra Clean Solutions

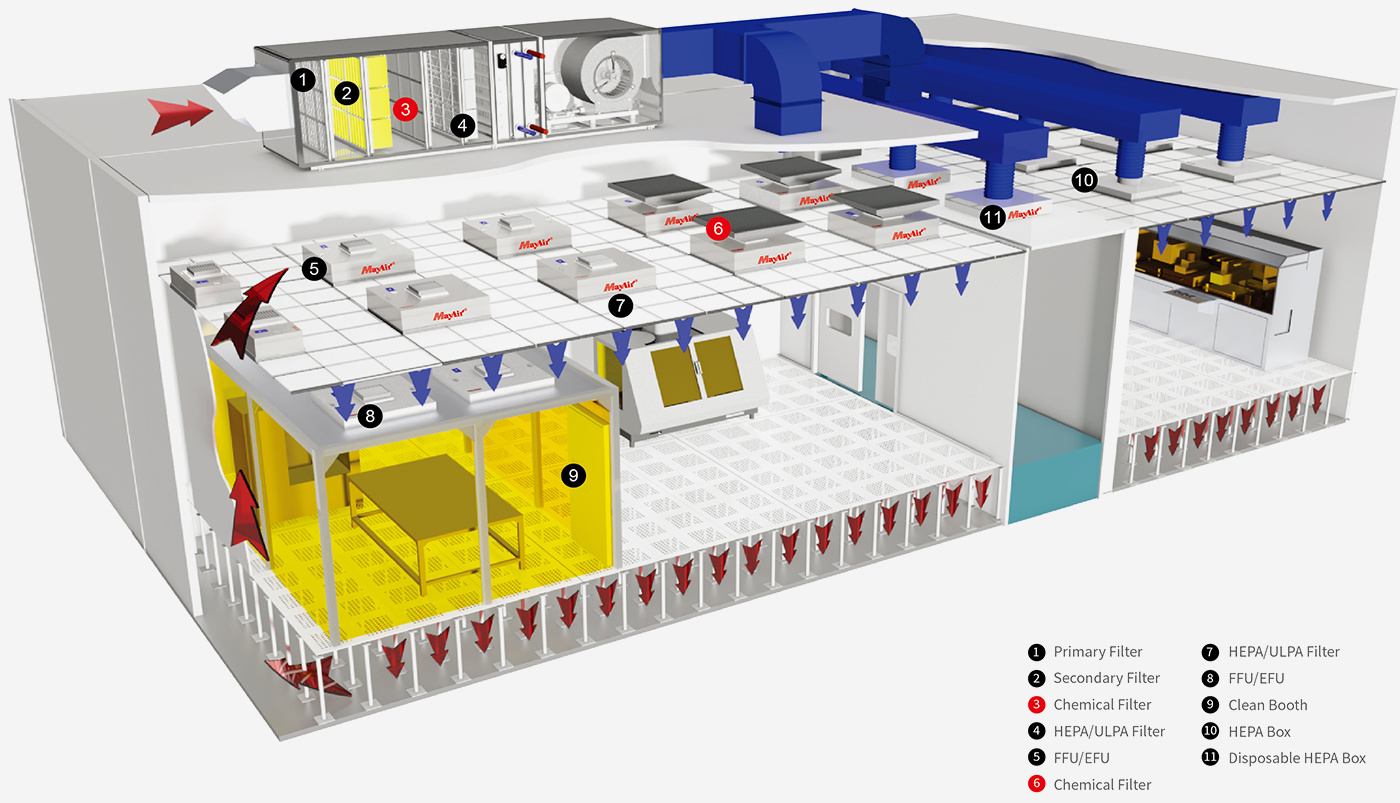

With the reduction of the critical line size of the line width of semiconductor chips, from the early micrometre (μm) level to the current nanometer (nm) level, the requirements for cleanliness throughout the chip manufacturing process are getting higher and higher. If the air cleanliness in the production process does not meet the requirements, the product yield will be badly affected. Almost all major sections in the integrated circuit supply chain, from single crystal silicon wafer manufacturing to IC manufacturing and assembly, need to be completed in a cleanroom. The requirements for cleanliness are very high. To maintain the cleanliness of the cleanroom, the semiconductor clean factory usually adopts a vertical unidirectional flow method. It exhausts the indoor polluted air to the outside through the push-out function to achieve the purpose of purifying the indoor air.

As one of the major suppliers, MayAir provides air purification products to local large-scale chip and LCD panel manufacturers, requiring high efficiency, low energy, and low noise equipment to facilitate their production processes. In addition, MayAir's products can help them meet the highest clean environment requirement.

Besides using FFU in a large area on the ceiling of a semiconductor or LCD panel factory to achieve vertical unidirectional flow, it is also necessary to strictly control the cleanliness of the machine controlling area. This is achieved by building a micro-environment or installing EFU at the machine's end in each area to meet stricter control standards of machine equipment.

Also, with the continuous improvement of process technology, it is no longer possible to improve the yield by controlling particulate matter alone. Airborne Molecular Contamination (AMC) control technology has become a necessary means to improve the yield of semiconductor products.