Applications|MayAir chemical filters help China's leading semiconductor companies after years of intensive cultivation

Release time:

2021-09-29

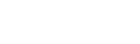

According to SEMI, the Semiconductor Equipment and Materials International, the equipment expenditure investment of 12-inch wafer fabrications increased by 16% in 2020 compared with last year, and it predicts that it will maintain a growth rate of 16% in 2021 and increase by 12% in 2022, exceeding 80 billion US dollars. As the Covid-19 epidemic accelerates the global digital transformation, and as 5G, electric vehicles, and smart wearables become more widespread, the demand for chips will see a spurt in the future.

China and the United States have gone from trade war to science and technology war since 2018, and there are many challenges in development of China’s semiconductor industry. However, in addition to upgrading the core technologies and manufacturing processes of independent research and development, the development also needs to consider factors such as infrastructures and construction. It is very important to build and maintain the clean workshop necessary for semiconductor manufacturing process among many links. Besides keeping the clean room in a constant temperature, constant humidity and ultra-clean dust-free environment, the influence of AMC should also be considered in key process areas.

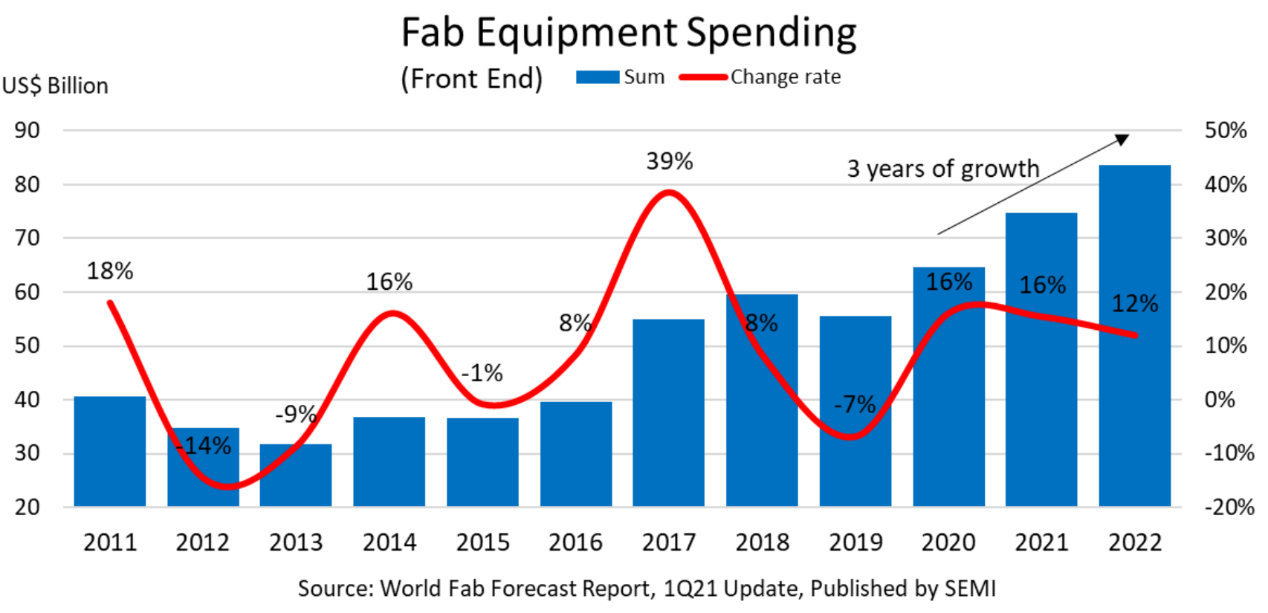

Classification of AMC

With the continuous upgrading and iteration of the manufacturing process, the yield can no longer be improved by controlling particulate matter alone, and the control technology of AMC (Airborne Molecular Contamination) has become a necessary means to improve the yield of semiconductors. MayAir has been serving the wafer fabrications in China since 2005, including one of the leading IC manufacturers in China.

The company was established in 2000 which is a well-equipped multinational integrated circuit manufacturing enterprise in mainland China. It can provide wafer foundry and technical services at different technical nodes from 0.35 microns to 14 nanometers, including logic chips, mixed signal/RF transceiver chips, high voltage resistant chips, system chips, flash memory chips, EEPROM chips, image sensor chips, power management, micro electromechanical systems, etc.

With the reduction of the key line width of wafers produced by this enterprise from 0.35 microns to 14 nanometer nodes, a slight deviation in the air quality in the working area will directly affect the yield of products. And the control for AMC is becoming more and more stringent. The environmental concentration of AMC in each area has strict control indicators and long-term monitoring, and MayAir has been providing AMC control services in clean rooms for customers.

Cooperating with the national strategy of chip localization, MayAir chemical filter department has also been intensively working on the product research and development of chemical filters Through more than ten years of cooperation with this customer. By increasing capital expenditures, investing in product R&D technology, and enhancing product performance and indicators in terms of energy conservation, noise reduction, and emission reduction, they meet the conditions of clean environment standards by the customers, promote production capacity improvements, and optimize product quality. We hope to grow together with our customers and help the development of "China Chip".