AMTS 2025 | Shanghai International Automotive Manufacturing Equipment Exhibition successfully concluded!

Release time:

2025-07-11

The AMTS 2025 Shanghai International Automotive Manufacturing Technology and Equipment and Materials Exhibition will be held from July 9th to 11th, 2025. The exhibition focuses on innovative design and manufacturing processes for new energy vehicles, gathering top global technological forces. MayAir, as a leader in the field of air purification, showcased efficient, safe, and reliable air purification solutions for the automotive manufacturing industry.

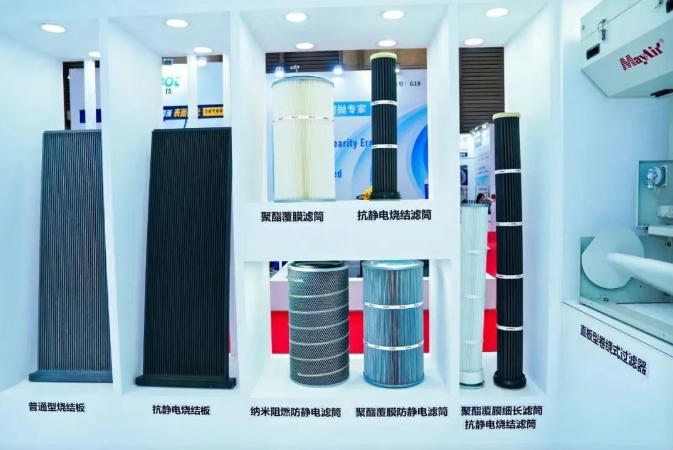

The core product matrix covers industry demand

The product matrix exhibited by MayAir this time is deeply in line with the stringent requirements of air purification in key aspects of automotive manufacturing.

Reliable guarantee for painting workshop

The high paint capacity of the coating series products can significantly reduce the number of shutdowns and replacements, effectively intercept spray paint mist, and ensure the continuous and efficient operation of the production line.

High temperature resistant filters can withstand temperatures up to 250 ℃, providing reliable support for the coating and baking process, ensuring long-lasting and stable coating quality.

The anti-static filter cartridge uses various conductive materials to eliminate safety hazards in powder processing scenarios.

Dust removal scene is safe and efficient

The laser cutting dust collector protects the environment and equipment safety through automatic spark capture and efficient treatment of submicron level smoke and dust.

The compact filter cartridge dust collector adopts an innovative structure to break through space limitations and achieve efficient dust removal with high air volume in limited spaces.

Full process purification of powder and comprehensive control of gas

The bag filter is designed with a large dust capacity and is not afraid of high dust load conditions.

The sintered plate series products are independently produced and developed, with imported technology localized, using rigid and tough formulas to provide long-term ultra clean filtration guarantee.

Chemical filters use customized filter materials to precisely control VOCs emissions, meeting increasingly stringent environmental regulations.

The replaceable filter is designed for easy replacement, effectively reducing maintenance costs and downtime.

Deepen service value and build comprehensive guarantee

MayAir always insists on providing customized solutions and a comprehensive quality assurance system for customers. By deeply understanding the unique working conditions of different customers, we provide customized purification system design solutions and quality assurance services throughout the equipment lifecycle to help customers optimize operating costs.

During the exhibition, the MayAir technical team was on-site to provide in-depth technical consultation and solution discussions for numerous visiting industry clients.

In the future, MayAir will continue to work together with partners in the automotive manufacturing industry to promote innovative air purification technology and move towards a greener, smarter, and more efficient direction in automotive manufacturing!