MayAir | Invited to attend the seminar on dust explosion prevention standards for rubber and plastic products, exploring new safety regulations together

Release time:

2025-04-14

On April 13, 2025, the seminar on dust explosion prevention standards for rubber and plastic products, hosted by the AQ4232-202x standard drafting working group, was successfully held in Taizhou, Jiangsu. The conference focused on dust explosion risk prevention and control, upgrading industry safety standards, and practical application of technology, attracting more than 100 representatives from emergency management bureaus, industry associations, research institutes, and more than 100 related enterprises across the country.

Mr. Ma Liang, Deputy General Manager of MayAir Environment, a brand under MayAir, was invited to attend the conference with technical representatives to share practical experience and technological achievements in the field of dust explosion prevention, providing important references for optimizing industry standards.

The AQ4232-202x standard was initiated and formulated by the Dust Explosion Prevention Technical Committee of the National Safety Production Standardization Technical Committee. It is a key technical specification for dust explosion prevention safety in the rubber and plastic products industry in China, focusing on core issues such as dust concentration control, equipment explosion prevention design, and process risk assessment.

Experts attending the meeting pointed out that with the expansion of industry production scale and technological iteration, there is an urgent need for more scientific and refined standard support for dust explosion risk prevention and control. The introduction of AQ4232-202x will fill some technical gaps and provide clear basis for the safety production of enterprises and the law enforcement of regulatory departments.

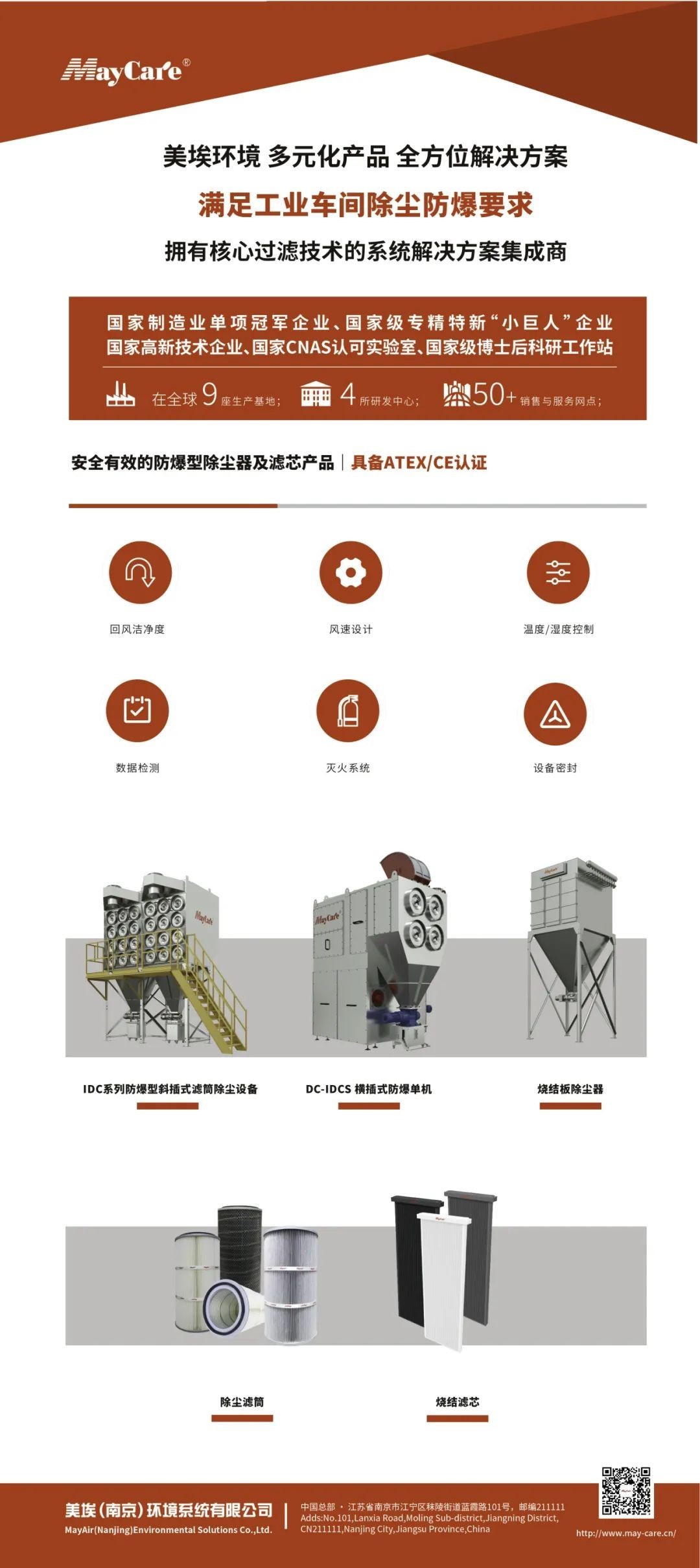

As the technical support unit of this seminar, MayAir Environment, based on years of experience in the field of explosion-proof dust removal, shared multiple typical cases with the attending representatives, analyzed in detail the causes and prevention difficulties of dust explosions in rubber and plastic production processes, and introduced the independently developed high-efficiency explosion-proof dust removal system.

As a system solution integrator with core filtration technology, MayAir Environment relies on its parent company MayAir's core research and manufacturing capabilities in the field of air purification. Multiple products have obtained ATEX and CE explosion-proof certifications, and has built a core technology moat in the field of dust explosion prevention, providing full chain dust explosion prevention solutions for multiple large enterprises.

During the meeting, MayAir Environment promised to continue to open up technical resources and actively cooperate with the working group to complete testing and optimization before the standard is implemented; And actively benchmark the new regulations in subsequent product design and implementation practices, truly building a safety bottom line through technological upgrades. MayAir Environment will also delve into the field of industrial environmental governance, providing technical diagnosis and equipment upgrade support for more enterprises, helping to reduce production risks, and building a green and safe production space.