Deeply cultivating technological innovation, exploring a new chapter in purification together | 2025CIPM Spring Pharmaceutical Machinery Exhibition successfully concluded

Release time:

2025-04-25

The 66th (Spring 2025) National Pharmaceutical Machinery Expo 2025 (Spring 2025) China International Pharmaceutical Machinery Expo will be held grandly in the mountainous city of Chongqing from April 23rd to 25th, 2025. This exhibition attracted over 1600 pharmaceutical equipment and service companies from 24 countries around the world to participate.

MayAir, with its latest research and development achievements and diverse product lineup, shines on stage. The exhibited products cover two major business sectors: biomedicine and industrial dust removal.

Biopharmaceutical Zone

Biosafety cabinet

The MayAir Biosafety Cabinet adopts a structure design with CNAS certified ULPA ultra high efficiency filters and negative pressure sealing, which can ensure that the cleanliness of the equipment working area reaches level 10. Built in UV lamp interlocking device and multiple high-precision sensors, efficiently protecting operators, products, and the environment. It can be applied in various laboratories and research institutes such as biomedicine, healthcare, genetic engineering, etc.

Clean workbench

A clean bench is one of the important equipment in a clean laboratory. It is not only a platform for operating experimental items, but also prevents external pollutants from entering the experiment. The MayAir clean bench adopts a negative pressure sealed structural design, coupled with CNAS certified HEPA high-efficiency filters, to ensure that the cleanliness of the equipment working area reaches level 100. Adopting a brushless DC motor and equipped with a high-precision differential pressure sensor, it ensures smooth air flow while reducing noise and energy consumption.

Industrial dust removal zone

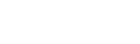

MayAir sintered plate

The filter element formed by calcination is used in conjunction with industrial dust collectors. The product has hydrophobicity and can be reused after washing, with a service life of up to 8-10 years. Compared with filter cartridges and bag filter elements, it is more environmentally friendly and durable. After being coated with film, it can have anti-static function and can be widely used in dust explosion-proof treatment production lines such as lithium batteries, rubber, powders, etc.

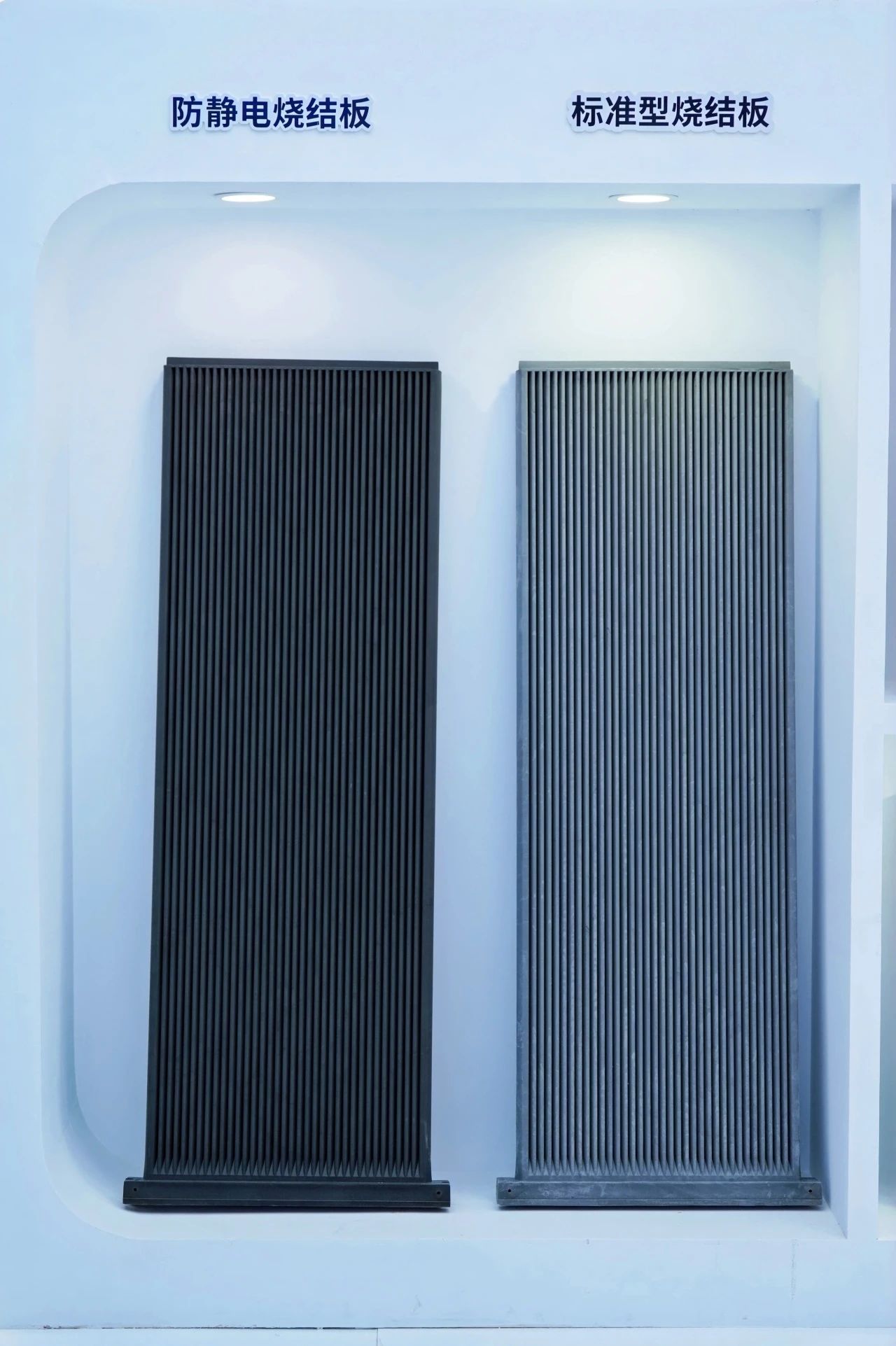

MayAir filter cartridge

The commonly used filter elements in dust removal equipment are applied in industries such as thermal power, medicine, food, new energy, metal smelting, rubber chemical, etc. MayAir filter cartridges can be equipped with filter element materials, end cap styles, strap materials, and corresponding sizes according to the needs of the production line. The structure is stable and has a high dust capture rate. The MayAir polyester coated anti-static filter cartridge and the nano flame retardant anti-static filter cartridge use special filter materials and grounding wires, which can effectively block static electricity and prevent explosion.

The exhibition booth attracted a lot of attention, gathering numerous industry experts, customers, and peers from home and abroad, attracting a large number of professionals to stop and exchange ideas. The sales and technical team of MayAir has conducted in-depth professional exchanges with various partners based on their rich industry experience and profound technical strength.

The team systematically explained the technical advantages and practical application of the product through detailed technical explanations and rich case introductions, and accurately answered various technical problems and industry questions. Frequent on-site interactions and lively discussions fully demonstrate the influence and technological strength of MayAir in the industry.

As an excellent manufacturer and service provider of air purification solutions, MayAir is committed to providing comprehensive support for the biopharmaceutical industry from clean rooms to laboratories, helping enterprises create high standard production environments. In the future, MayAir will continue to deepen technological innovation, continuously optimize products and services, work together with industry partners to promote the development of China's pharmaceutical equipment industry to a higher level, and inject stronger purification power into the industry's development.